FSL is committed to providing highly efficient technical solutions for drilling & completion, including innovative products such as near-bit tools and continuous circulation drilling systems. Below are several core drilling technology products from FSL, designed to enhance drilling efficiency, reduce costs, and effectively address complex geological conditions.

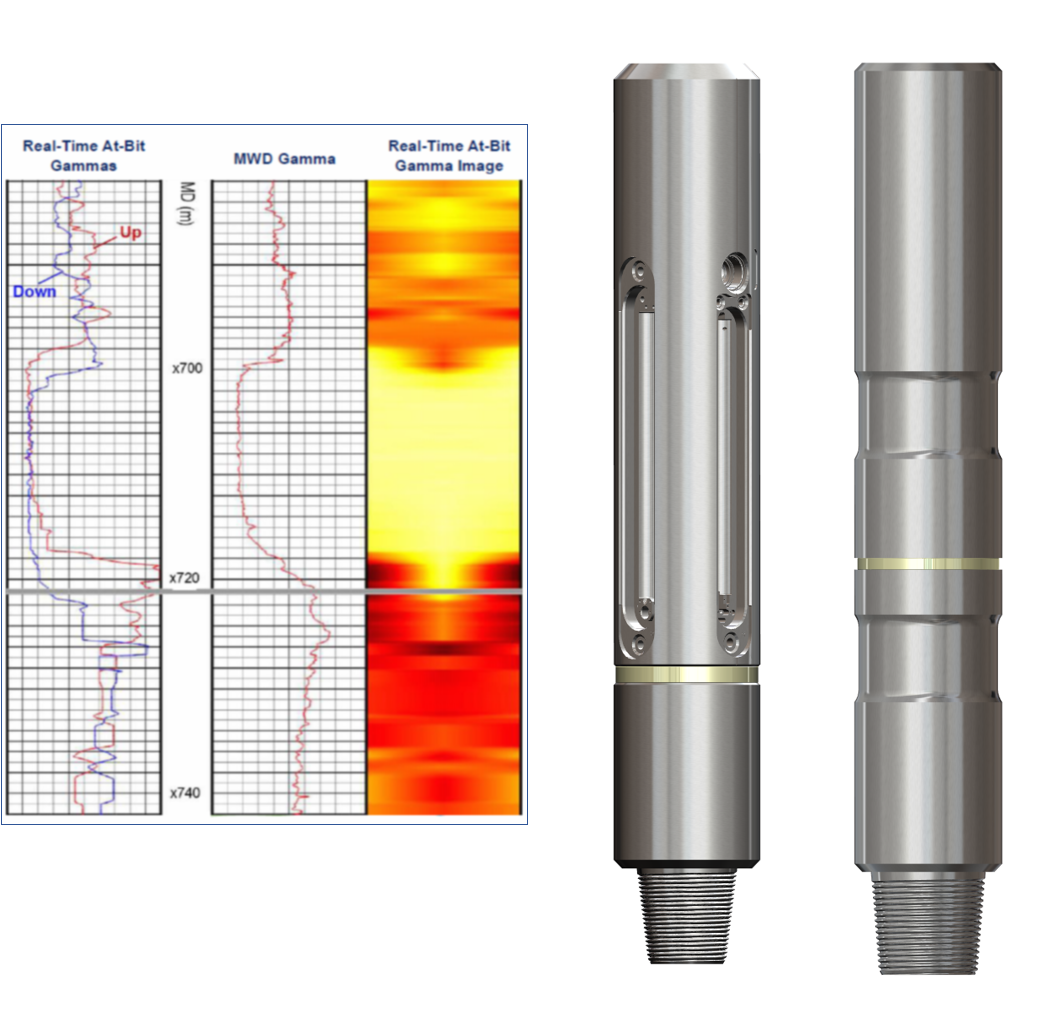

Near-Bit Az GR Sub: The near-bit sub measures short sections of the drill string and sends radio current signals. The receiver receives and decodes the signals, which are then sent to the MWD (Measurement While Drilling) tool for data encoding and transmission. Finally, the data is received and decoded by surface equipment through mud pulse signals, providing downhole Az GR measurement data.

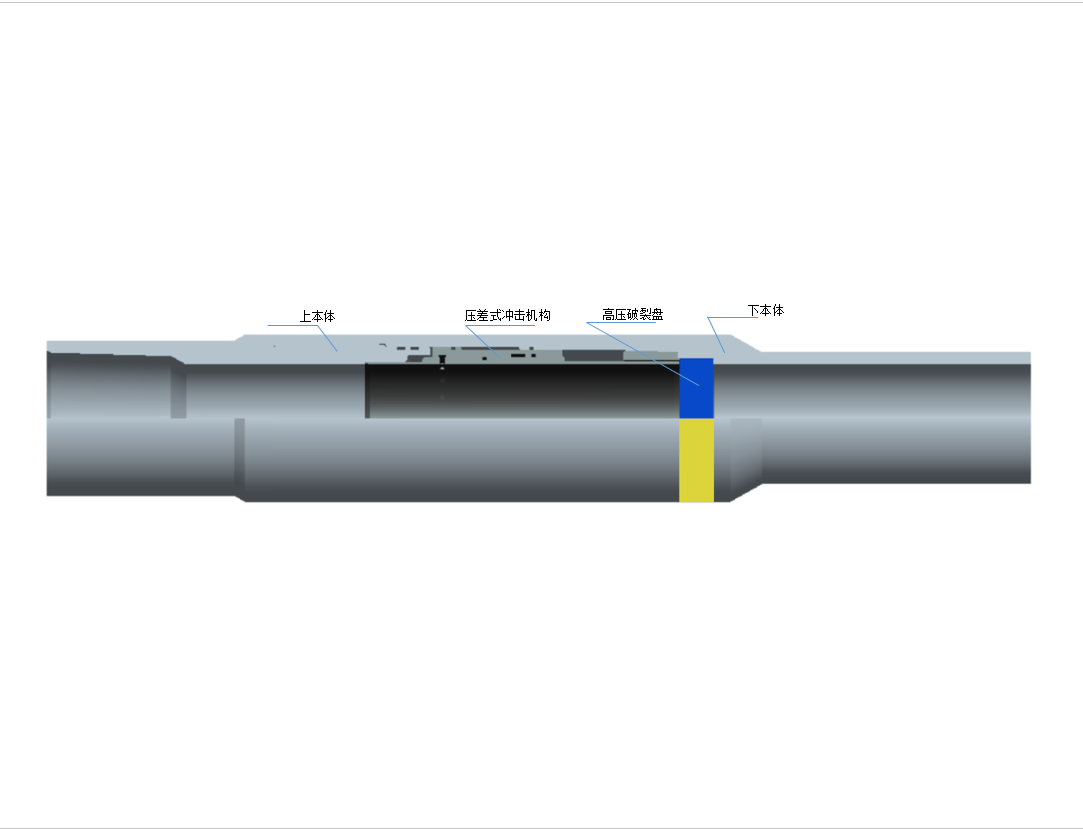

Continuous Circulation Drilling System: The continuous circulation system maintains continuous circulation of drilling fluid during the process of making up and breaking-off the connection of drill strings, providing stable bottomhole ECD (Equivalent Circulating Density) and wellbore cleaning. This enhances drilling continuity and safety, reduces downtime, and improves overall drilling efficiency. The system also minimizes the risk of wellbore instability and prevents the intrusion of formation fluids during conventional drilling connection when making up and breaking-off the connection of drill strings, thereby enhancing safety.

Mechanical Top Drive Casing Running Tool: An innovative product designed to improve the efficiency, safety, and quality of oil and gas drilling operations. By enhancing the safety, efficiency, and quality of casing running operations, this tool significantly boosts overall drilling efficiency. It effectively addresses common issues in traditional casing running, such as stuck pipe, break circulation difficulties, and potential formation fluid influx. It also provides more reliable operational support in complex and harsh geological environments, offering stronger technical assurance for oil and gas development.

Floating Casing Collar: The floating casing collar uses the buoyancy of air or low-density drilling fluid enclosed between the casing shoe and the intermediate casing to reduce the friction between the casing and the wellbore during casing running, ensuring safe and smooth casing installation.