Since the advent of horizontal wells and extended reach wells, ensuring the safe running of casing, especially for extended reach horizontal wells, has remained a significant technical challenge. Based on extensive research and testing both domestically and internationally, casing floating sub running technology is considered one of the most effective methods to address casing running difficulties. This technology involves adding floating couplings to the casing string structure, utilizing the buoyant force of the air or low-density drilling fluid enclosed between the casing shoe and the floating coupling to reduce the friction between the casing and the wellbore during the casing running process, ensuring safe casing running.

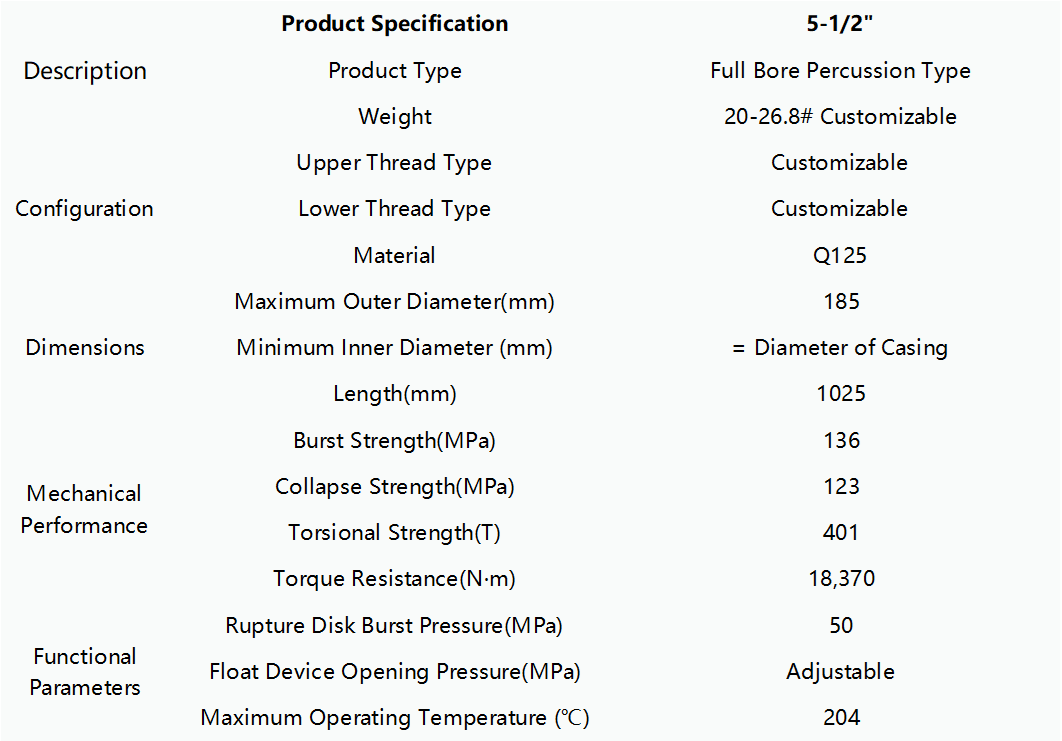

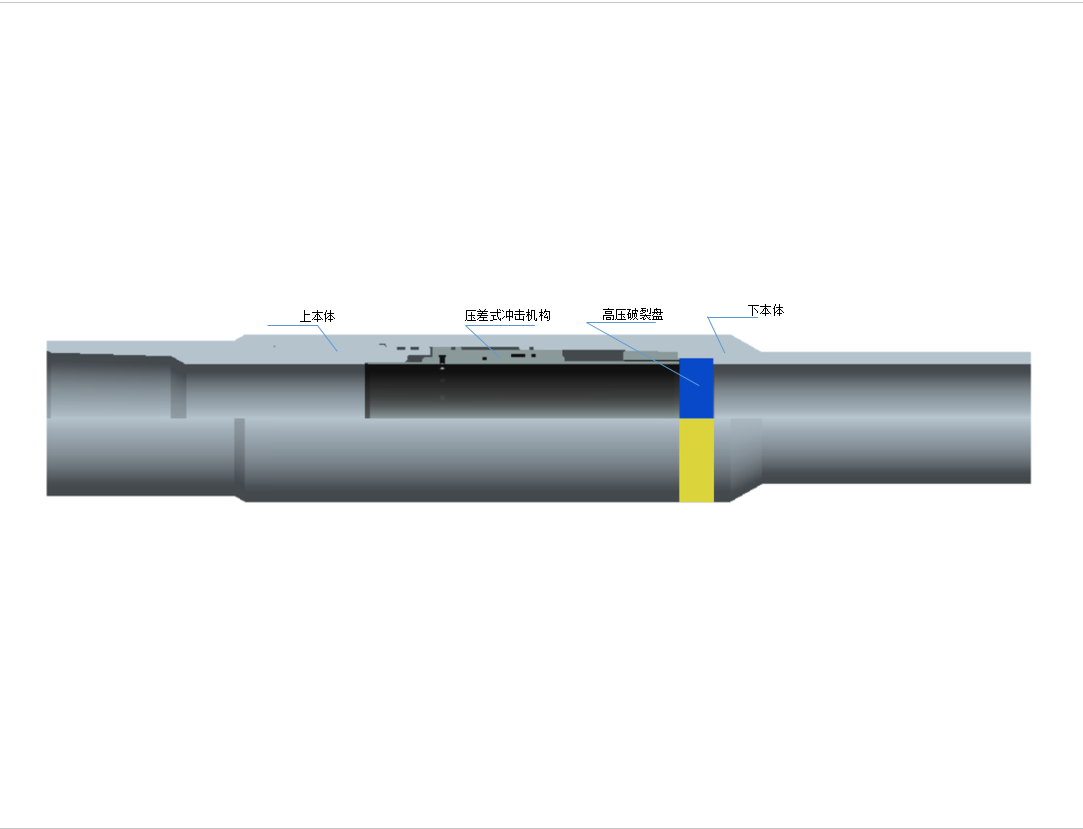

FSL's IF series casing floating sub features a high-pressure-rated, high-compressive strength rupture disk, and incorporates a differential pressure impact mechanism to assist in breaking the rupture disk. This design not only meets the deep well operational requirements but also provides the capability to adjust the rupture pressure of the floating coupling on-site according to the actual well conditions.