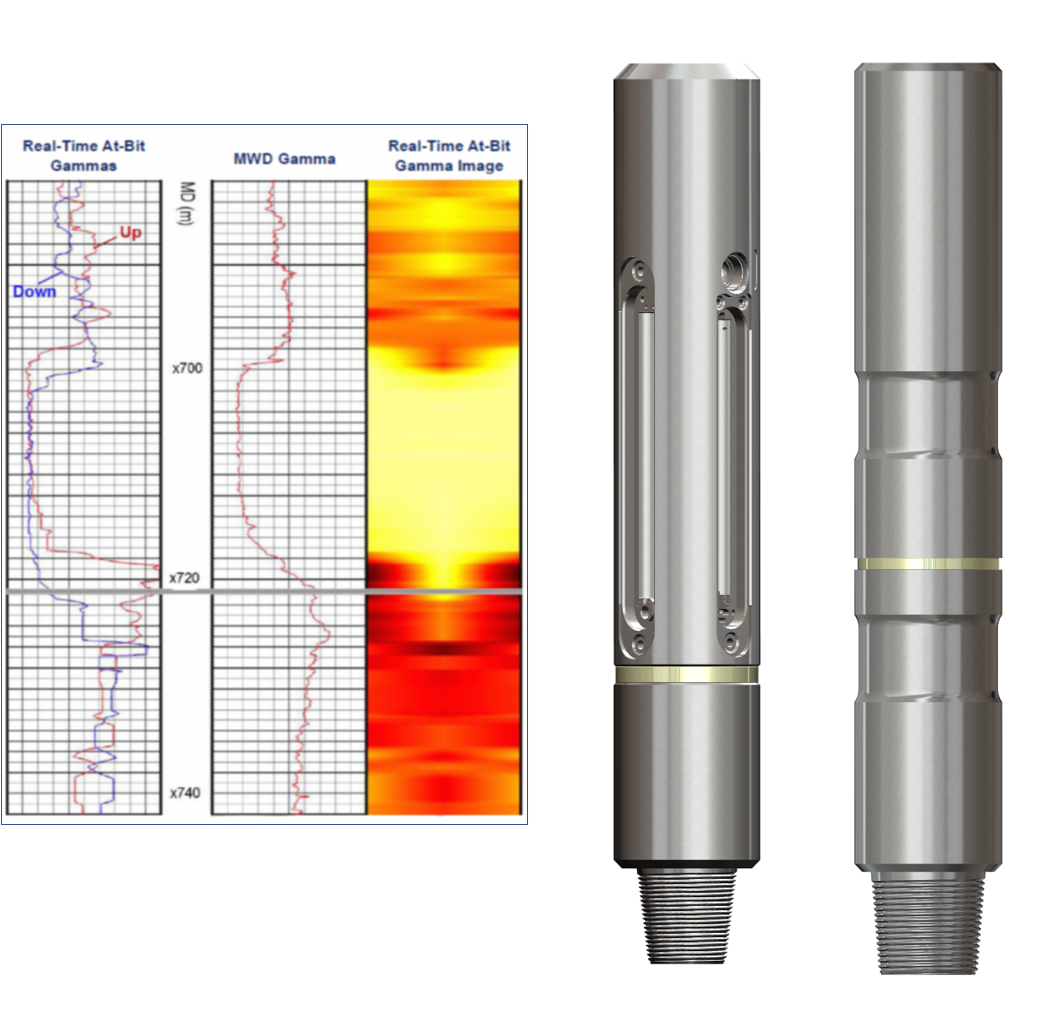

The Near-Bit Az GR Sub measures the Gammer reading of formation by sending radio current signal. The receiver receives and decodes the signals, which are then sent to the MWD (Measurement While Drilling) tool for data encoding and transmission. Finally, the data is received and decoded by surface equipment through mud pulse signals, providing downhole Az GR measurement data.

The At-Bit system, located close to the drill bit, utilizes wireless short-range communication to send measurement data from the Near-Bit Sub via MWD (Measurement While Drilling) in real-time. It is capable of measuring various parameters such as bottomhole inclination, temperature, RPM (revolutions per minute), downhole vibrations, and near-bit azimuthal gamma data, providing critical information for interpreting formation changes and significantly enhancing geological steering capabilities.

FSL's R&D team overcame several challenges related to materials, thin-walled casing mechanics, connection design for various compartments, five-axis precision machining processes, signal transmission, and insulation design through extensive research on Near-Bit Sub and accessories. This led to the successful design and manufacturing of the tool.

Through numerous experimental trials, adjustments, testing, and finalization of the insulation material, insulation glue, threads, and assembly processes, the team ensured a 100% success rate for the installation of tools with mega-ohm level insulation.