- Company

- News room

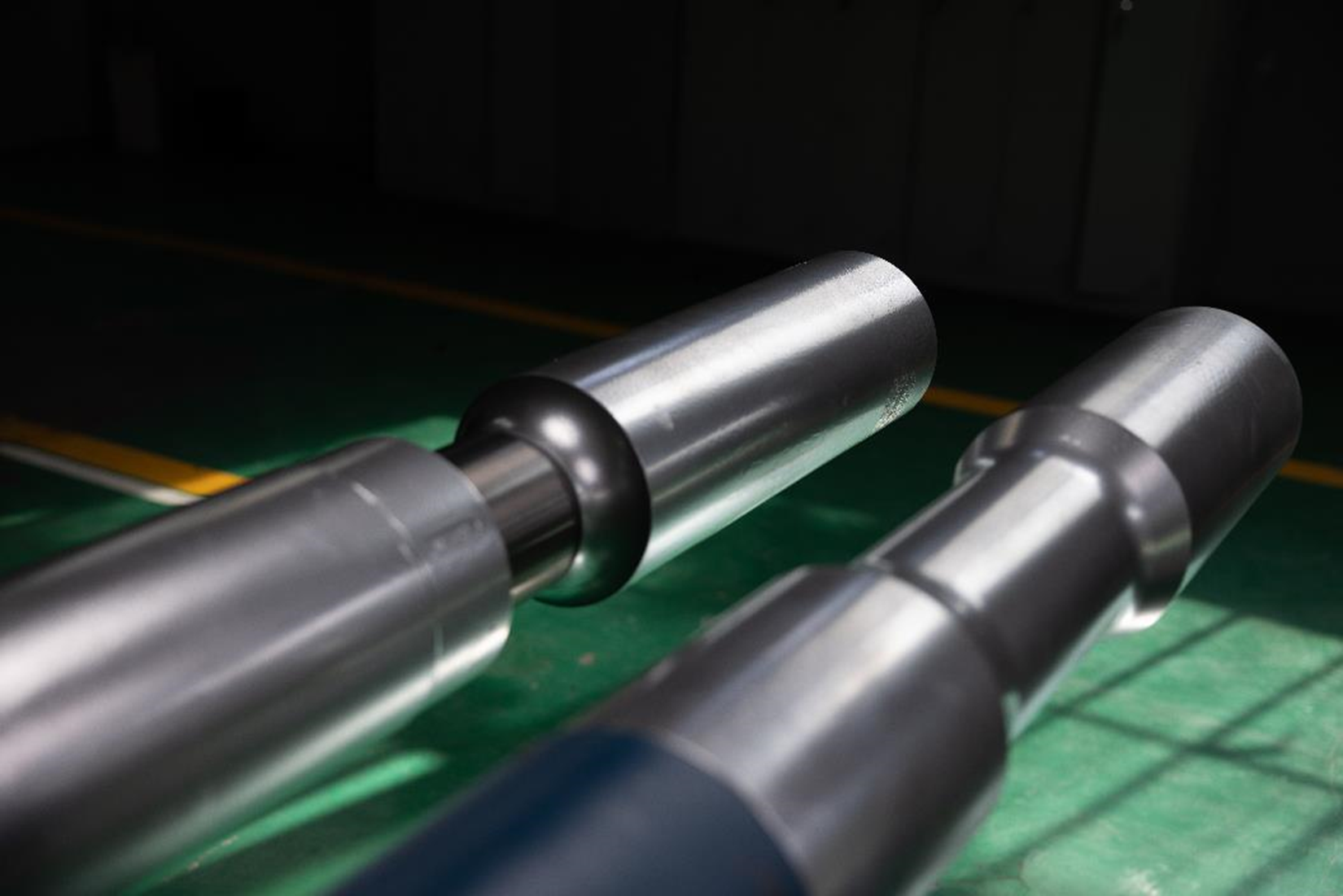

- First Shipment of Hydro Thrusters to Middle East for enhanced drilling efficiency.

FSL is proud to announce that the company's first batch of Hydro Thrusters has been successfully shipped to the Middle East in September 2024, marking a significant milestone in the company's global expansion and its efforts to enhance drilling efficiency.

The Hydro Thrusters are designed to improve the effectiveness of drilling efficiency by reducing the friction between the bottom hole assembly and the wellbore. This results in better weight on bit transfer, alleviates or eliminates issues such as stick-slip vibrations, drag, pressure variations, unstable toolface, and stuck pipe, while increasing the rate of penetration (ROP) and reducing downtime. As the number of extended reach wells and horizontal displacements wells continues to grow, the challenges in drilling modes are becoming more significant. FSL's Hydro Thruster addresses this issue in a simple and effective manner. The smooth transmission of weight on bit improves the adjustment capabilities of the toolface, even in complex formations with significant azimuth changes, allowing for deeper reaches into target zones. During drilling, minimal adjustment of the toolface is needed, maintaining stability and enhancing drilling efficiency.

This shipment highlights FSL's commitment to meeting the specific needs of customers, especially in demanding operational environments. The use of Hydro Thrusters is expected to significantly improve drilling efficiency, enabling clients to achieve faster drilling speeds and better wellbore placement, while reducing overall operational costs.

FSL will continue to provide high-quality and innovative solutions to the energy industry, focusing on improving the performance, safety, and cost-effectiveness of operators worldwide.